Q&A

A bronze electronic part plated with tin shorted due to the growth of a whisker. What are the causes and the countermeasures for it?

The cause of the generation of a whisker is due to the internal stress due to the volume change of intermetallics that is formed by the diffusion of copper and tin.

The countermeasures to prevent the generation of whisker include

The countermeasures to prevent the generation of whisker include

- plate Ni as a diffusion barrier

- reflow tin plating

- heat-treat with 150℃ for an hour after tin plating

- use tin alloy plating instead of tin plating (ex. Sn-Ag, Sn-Bi)

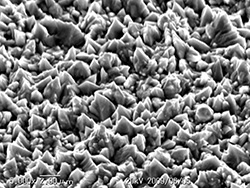

Is there any method to make the adhension of mold resin and iron stronger?

We suggest a nickel plating that has a needle-like rough surface due to the control of the solution composition of nickel solution.

the surface of roughening Ni plating

the surface of roughening Ni plating

Is it possible to mass-produce at the factory in Malaysia after producing experimentally in Japan?

Yes, it is. However, if it is difficult to handle the production with the existence equipment in Malaysia, we need to create new equipment and send it to Malaysia.

Do you guys sell your plating equipment?

No, we do not. We are developing and produce our equipment internally in order to to distinguish ourselves from our competitors.

Is it okay to ask for test production only?

You are more than welcome.

To what extent (thickness) can you plate?

We can plate as thick as you want to.

To what extent (size) can you plate?

If it is nickel plating, the maximal length we can plate is 550mm, and maximal weight is about 2kg.

Can you plate on aluminum and stainless. steel?

Yes, we can. Please ask us if you want to plate on the other materials.

Do you plate bright Ag plating?

Yes, we do. The degree of brightness is 1.2-1.8.

Please tell me about hard gold plating.

The degree of purity of hard gold is about 99.7%. By adding cobalt, we make gold cobalt alloy. Hard gold is plated for contact mechanism.

Please tell me about soft gold plating.

The degree of purity of soft gold is about 99.9%.

It is pure gold plating.

It is used for wire bonding of lead frame.

It is pure gold plating.

It is used for wire bonding of lead frame.

Could you tell me how you distinguish the degree of brightness of dull nickel, semi bright nickel, and bright nickel?

individuals’ and companies’ sensory classification. Just for information, we use a numerical number measured by a reflected density indicator ND-11 from Nippon Denshoku Industries co., Ltd. to categorize them.

- Dull : 0.1-0.5

- Semi bright : 0.6-1.2

- Bright : 1.3-1.9

- Super Bright : 2.0-2.4

Is it possible to do a collaborative development with you?

Yes it is. We have experience of collaborating in development with our customers.

Can we ask you to analyze the defective goods plated by the other plating companies?

Yes. There is a charge for this request but it is much cheaper compared to a private analytical body.

Internal production of All Lines

Internal production of All Lines